The resource of water is an intrinsic part of the production of SWAROVSKI OPTIK products, which makes mindful and efficient consumption particularly important to us. Our factory in Absam is located in a region with abundant water supplies, but we still continuously seek out innovations to ensure sparing and sustainable use of this natural resource.

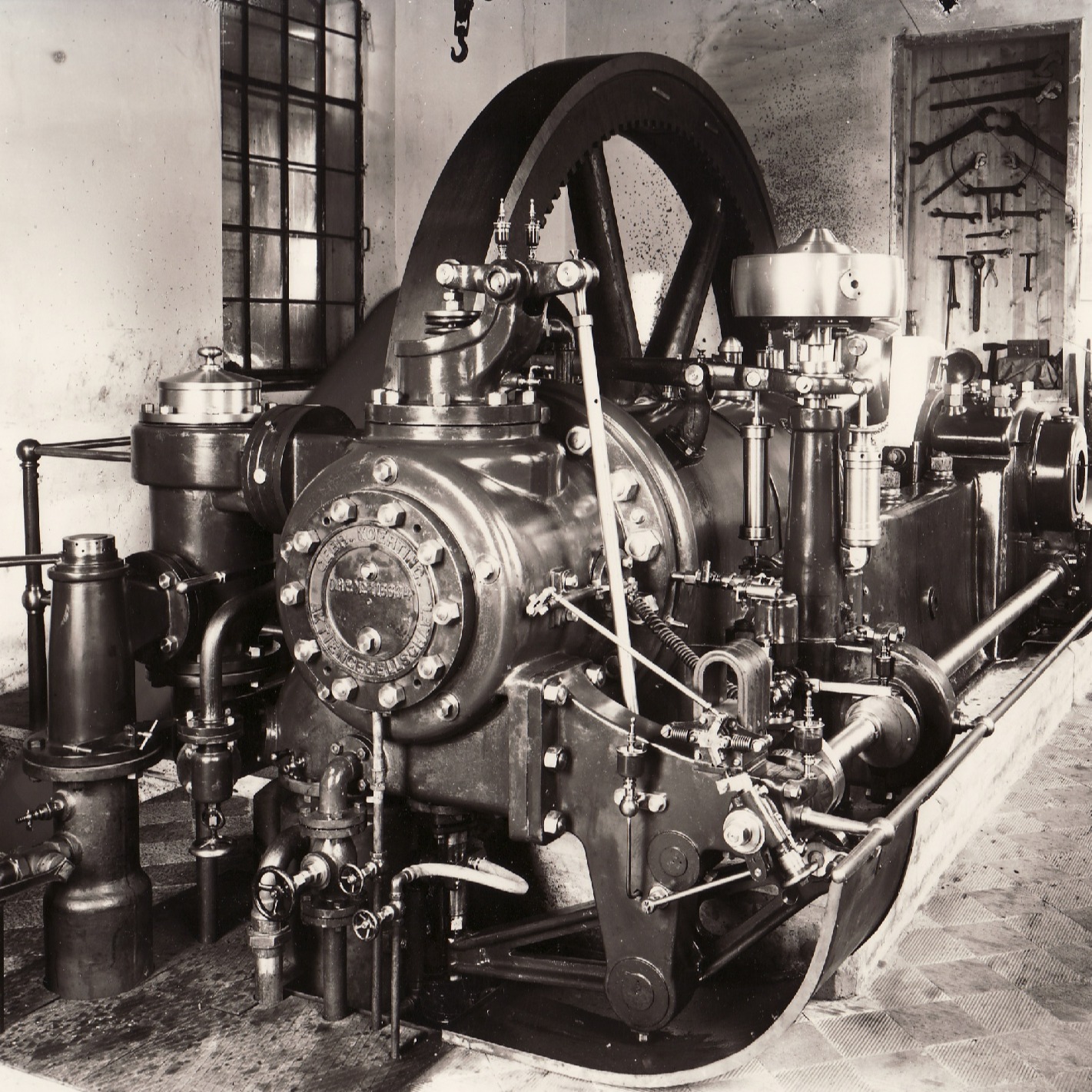

Even in 1895, when the SWAROVSKI crystal-cutting factory was founded in the Tyrolean town of Wattens, efficient use of water and the associated energy was a crucial consideration. And this was no less important for Wilhelm Swarovski in 1949 when he created his company SWAROVSKI OPTIK in Absam. Since then, the power of water and its sustainable use within the company have played a decisive role in many areas:

INNOVATIVE ENERGY RECOVERY

Modern recycling processes make it possible to reuse energy in production. For example, the anodizing plant built in 2020 allows direct reuse of wastewater from the chemical process at a temperature of 94°C (201°F). Rather than leaving the water for hours to cool, the heat is extracted and then used to heat the entire building. We have also completely eliminated the use of cooling water for the air compressors in optical manufacturing and instead use heat-recovery systems to transfer the resulting energy to hot water pools and heating appliances. This loop keeps water and energy consumption as low as possible.

WASTEWATER TREATMENT

Fresh water for production comes exclusively from the municipality of Absam. It is used mainly for surface treatments and processing of mechanical and optical components. We strive to keep this consumption as low as possible and have introduced various measures to reduce fresh water requirements for washing installations. The anodizing plant has a large, highly efficient system to clean chemically concentrated wastewater. This carefully removes all chemicals from the water, which is then treated in vacuum vaporizers. It can then either be fed back into the system as rinsing water or channeled into a separate sewage system as industrial effluent after checks of the pH level. The pH level is monitored 24/7. Additionally, precise analyses are conducted every two months. Appropriate purification of wastewater is also an intrinsic part of the other production steps within the company, even extending to the fat separator in the “Zum Habicht” canteen.

FAR-SIGHTED CONSERVATION OF RESOURCES

SWAROVSKI OPTIK’s efforts to ensure sparing and sustainable use of the resource of water extend beyond its own requirements. The company works at a regional and international level to raise awareness of this essential element and its unequal distribution around the world. We liaise closely with the Swarovski Waterschool and work together to plan activities for the future. Since 2000, this successful project has been educating children from 8 to 13 years of age in the importance of conserving water. The Swarovski Waterschool’s program is now available internationally in Brazil, China, India, Thailand, Uganda, and the US. Depending on the location, the curriculum focuses either on access to drinking water and sanitary facilities, or on developing knowledge of water and the environment.